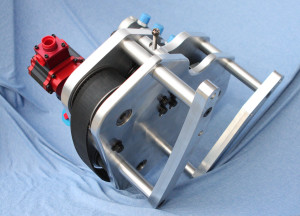

Our Front Drive provides the ultimate in reliability and convenience.

- Configurations available for a wide variety of pump make/models. Bolt patterns and mounting provisions have been developed for a wide variety of pumps so far. The most common have been: Aviad, Vickers, Waterman, Tuthill, MSD magneto, and HyPro. If you are interested in other accessories, please contact us.

- The assembled unit weighs less than 40 pounds, including the belt.

Specifications

- Bearings in the lightened front and rear plates support both ends of each pulley and idler. Although this system has three drive positions, several customers have used it to drive only two accessories – leaving the third position available in case they decide to implement a third pump in the future.

- The design provides nearly 180 degrees of belt engagement on each pulley.

- The drive belt can remain in place and tight while pumps are removed/installed. Belt tension is easily adjusted with a threaded tightener, then bolts are tightened to secure the sliding idler in the desired position.

- Each drive shaft has a bore and key-way specific to the pump it drives.

- Various sizes of pulleys are available so pump drive ratios can be tailored to individual needs. Drive ratios available range from 50% to 140%. Others may be created upon request. The drive ratios can be altered on any drive system by changing pulleys, idler positions, and sometimes belt length.The drive can be mounted on any make/model of tractor – only the mount brackets are different. To date, we have developed and shipped drives for big and small block John Deere, IH, and Perkins V8. We will develop others upon request.

- Both the front and rear of the drive can drive various items, six accessories could be driven with this system.

- The same drive system can be mounted on any tractor – only the block mounting plates differ.

Coming Soon

- A two pump design which will be much lighter.

- A two pump design with an integrated light weight starter and flywheel.